Back in 2009, TIME magazine featured biobanks among “10 Ideas Changing the World Right Now”.

Fast forward to today, with an increase in omics technology and a shift towards precision medicine, biobanks have become an indispensable requisite for biomedical research.

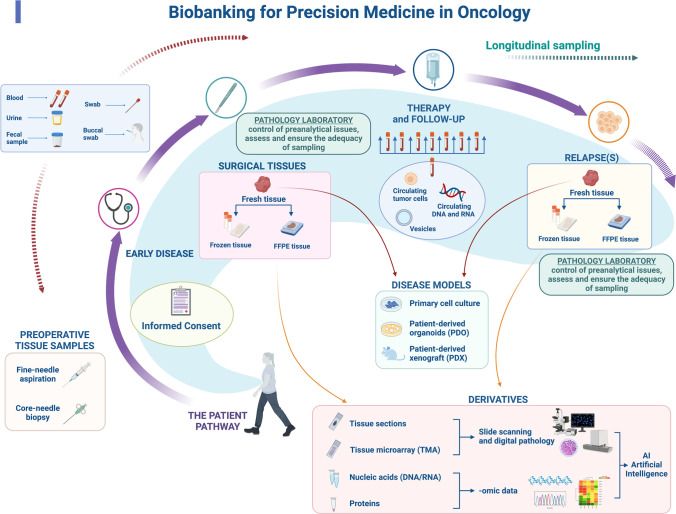

Biobanks are catering to national, regional, and disease-specific needs. The facilities store a diverse array of samples, from frozen cell aliquots for pharmaceutical screening to tissue biopsies and patient DNA samples, for targeted therapies to population-wide studies.

Consider cancer research.

Already, dozens of genes have been linked to cancers. Imagine the power of the stored samples written 100,000 or even millions of times larger, over not just cancer but also other diseases.

The idea is to analyze genetic profiles, identify biomarkers, and develop targeted therapies tailored to individual patients.

Cancer hospitals have been preserving tissue samples to enhance therapeutic strategies and understand disease progression better.

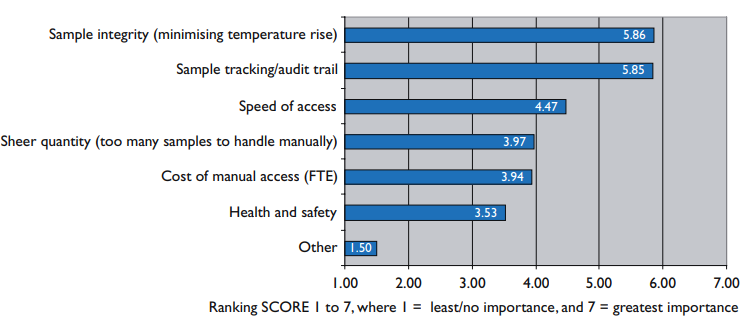

Despite the wealth of samples, there’s a bottleneck: the quality of the data obtained from some stored samples hasn’t always been optimal.

This has of course impacted the data obtained from the downstream analysis.

Is there a solution on the line?

Automation.

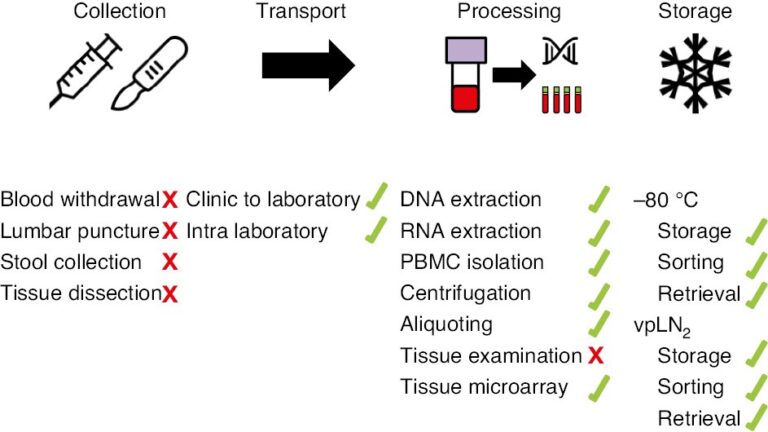

While sample collection and storage remain predominantly manual, automation has revolutionized other aspects of biobanking, notably sample tracking and data management.

Imagine the nightmare of misplacing notes or having stickers peel off tubes stored at sub-zero temperatures. It’s more common than you’d think.

This is where Laboratory Information Management Systems (LIMS) or Biobank Information Management Systems (BIMS) step in. These systems have transformed sample storage and management, replacing labor-intensive manual processes with automated tracking and data entry.

Take the UK Biobank, for instance. Established in 2007, it’s one of the largest biobanks globally. With over 500,000 donors, each sample is meticulously linked to medical records, facilitating longitudinal health studies to uncover new biomarkers and disease relationships.

At full capacity, the UK Biobank can store upwards of 15 million samples divided into a working and backup archive.

They, of course, track and maintain samples using a commercially available LIMS called Nautilus.

In the Indian context, the government has initiated funding for the establishment of biobanks. Presently, there are about nineteen biobanks, including the Bangalore Brain Bank, Tata Memorial Hospital Tissue Bank, and TCG Life Sciences Biobank among others.

There’s a unique facet here though.

The diverse population complicates sample collection and processing.

This makes it absolutely necessary for the system to be robust.

Barcoded tubes streamline sample identification and tracking, minimizing errors and enhancing operational efficiency. Integration with LIMS further facilitates automated data capture, ensuring data integrity and fostering collaboration among research institutions.

How can we help?

Manta, the nucleic acid extraction device automates the sample preparation process. It uses pre-filled cartridges with magnetic rods which take it through the lysis, binding, washing, and elution steps.

It offers a choice in the last step – to elute either in the same cartridge or a separate barcoded tube.

This automates the entire process, minimizes the risk of cross-contamination, and keeps the extracted nucleic acid intact.

Looking ahead, the trajectory is clear: automation and barcode technology will continue to redefine biobank operations.

We are committed to facilitating this transition. If introducing automation NA extraction with barcoded elution tubes is something your lab is interested in, please reach out👇